Product

Human Respect Development Center, DKS HRDC

DKS Propping System

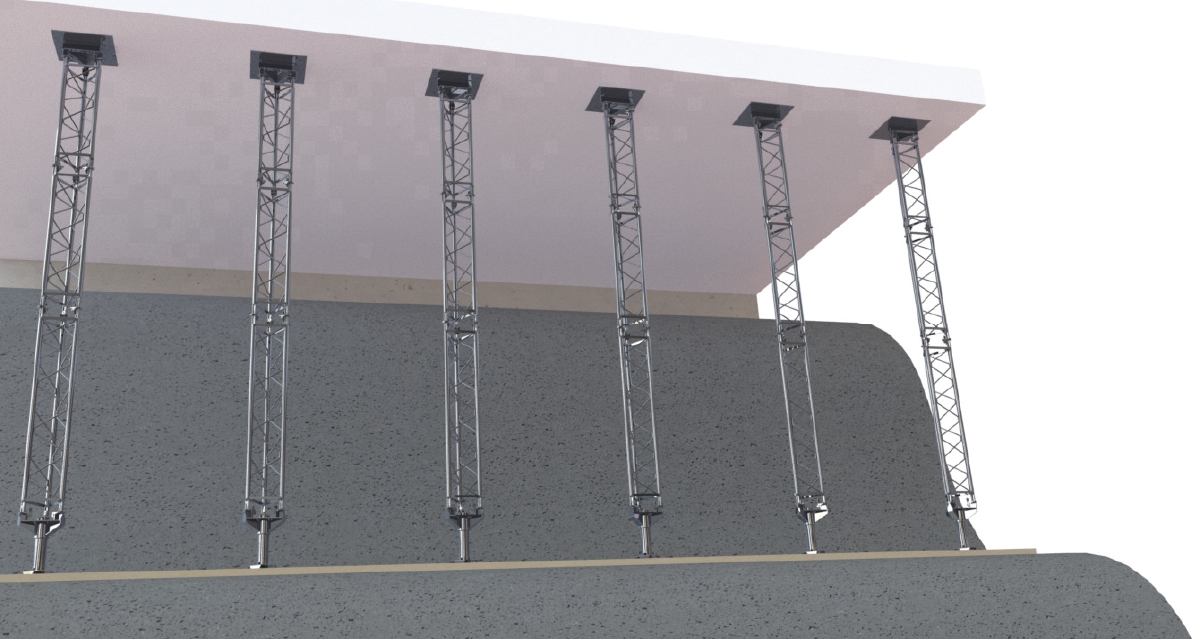

Human Respect Development Center

- Needling project that required additional interior support to accommodate the removal of the floors and roof

- Building loads were supported externally while renovations were completed

- Shoring towers inside buildings

- Shoring towers for bridges

- Building loads were supported externally while renovations were completed

- Shoring towers inside buildings

- Shoring towers for bridges

Overview

-

-

-

ShoreHire Construction site, Australia. Manufacturer. DKS Global

-

-

-

-

-

-

-

-

Coates Hire Construction site, Austrailia, Manufacturer, DKS Global

-

Coates Hire Construction site, Austrailia, Manufacturer, DKS Global

Propping System 60

Safety System Beam is the latest addition to D.K.S lar ge propping systems based around the prop unit which has nominal safe axial load of 60 tonnes.

This extremely versatile modular system comprising bracing members, grillage, needle beams and an extensive range of ancillary components is more than capable of providing a safe and economical solution for medium, to heavy-duty propping applications.

This extremely versatile modular system comprising bracing members, grillage, needle beams and an extensive range of ancillary components is more than capable of providing a safe and economical solution for medium, to heavy-duty propping applications.

- mm/kg

- in/lb

| DESCRIPTION | LENGTH | WEIGHT |

|---|---|---|

| System 60 100mm Section | 100mm | 18kg |

| System 60 125mm Section | 125mm | 19kg |

| System 60 250mm Section | 250mm | 23kg |

| System 60 500mm Section | 500mm | 33kg |

| System 60 1000mm Section | 1000mm | 54kg |

| System 60 1500mm Section | 1500mm | 76kg |

| System 60 2000mm Section | 2000mm | 96kg |

| DESCRIPTION | LENGTH | WEIGHT |

|---|---|---|

| System 60 100mm Section | 3.9 in | 39.7 Ib |

| System 60 125mm Section | 4.9 in | 41.9 Ib |

| System 60 250mm Section | 9.8 in | 50.7 Ib |

| System 60 500mm Section | 19.7 in | 72.8 Ib |

| System 60 1000mm Section | 39.4 in | 119.0 Ib |

| System 60 1500mm Section | 59.1 in | 167.6 Ib |

| System 60 2000mm Section | 78.7 in | 211.6 Ib |

SYSTEM 60 ACCESSORIES

| DESCRIPTION |

|---|

| 1. System 30 Jack |

| 2. Raking Bracket |

| 3. End Plate |

| 4. End Connector |

| 5. Needle Beam Fixing Clamp |

| 6. Truss Fixing Bracket |

SYSTEM 60 SCREW JACK SPECIFICATIONS

| DESCRIPTION | WEIGHT | ADJUSTMENT | BASE |

|---|---|---|---|

| Screw Jack | 32kg | 400 - 610mm | 250 - 250mm |

Propping System 30

Safety System Beam is the latest addition to D.K.S large propping systems based around the prop unit which has nominal safe axial

load of 60 tonnes.

This extremely versatile modular system comprising bracing members, grillage, needle beams and an extensive range of ancillary

components is more than capable of providing a safe and economical solution for medium, to heavy-duty propping applications.

load of 60 tonnes.

This extremely versatile modular system comprising bracing members, grillage, needle beams and an extensive range of ancillary

components is more than capable of providing a safe and economical solution for medium, to heavy-duty propping applications.

- mm/kg

- in/lb

| DESCRIPTION | LENGTH | WEIGHT |

|---|---|---|

| System 30 125mm Section | 125mm | 8kg |

| System 30 250mm Section | 250mm | 11kg |

| System 30 500mm Section | 500mm | 17kg |

| System 30 1000mm Section | 1000mm | 30kg |

| System 30 1500mm Section | 1500mm | 42kg |

| System 30 2000mm Section | 2000mm | 55kg |

| DESCRIPTION | LENGTH | WEIGHT |

|---|---|---|

| System 30 125mm Section | 4.9 in | 17.6 Ib |

| System 30 250mm Section | 9.8 in | 24.6 Ib |

| System 30 500mm Section | 19.7 in | 37.5 Ib |

| System 30 1000mm Section | 39.4 in | 66.1 Ib |

| System 30 1500mm Section | 59.1 in | 92.6 Ib |

| System 30 2000mm Section | 78.7 in | 121.3 Ib |

SYSTEM 30 ACCESSORIES

| DESCRIPTION |

|---|

| 1. System 30 Jack |

| 2. Raking Bracket |

| 3. End Plate |

| 4. End Connector |

| 5. Needle Beam Fixing Clamp |

| 6. Truss Fixing Bracket |

SYSTEM 30 SCREW JACK SPECIFICATIONS

| DESCRIPTION | WEIGHT | ADJUSTMENT | BASE |

|---|---|---|---|

| Screw Jack | 25kg | 400 - 610mm | 190 - 190mm |

Propping System 15

Universal System 15 is the latest addition to the Coates Hire Support System range of propping. It can connect to the System 30 as well as System 60 to provide a versatile propping system.

Besides being used as a compression member, this system has found use as a f orm work soldier, a r aking prop and also as abraacing where it pr ovides an ef ficient load carrying capacity for the loads up to 160kN. The se ction of the System 15 prop is 140×190mm.

M14 N, B&W are required to connect memb ers and accessories of System 15 to gether.

Besides being used as a compression member, this system has found use as a f orm work soldier, a r aking prop and also as abraacing where it pr ovides an ef ficient load carrying capacity for the loads up to 160kN. The se ction of the System 15 prop is 140×190mm.

M14 N, B&W are required to connect memb ers and accessories of System 15 to gether.

UNIVERSAL PROP SYSTEM 15 SPECIFICATIONS

- mm/kg

- in/lb

| DESCRIPTION | LENGTH | WEIGHT |

|---|---|---|

| System 15 125mm Section | 125mm | 5.5kg |

| System 15 250mm Section | 250mm | 8kg |

| System 15 500mm Section | 500mm | 12kg |

| System 15 1000mm Section | 1000mm | 21kg |

| System 15 2000mm Section | 2000mm | 38kg |

| DESCRIPTION | LENGTH | WEIGHT |

|---|---|---|

| System 15 125mm Section | 12.13 in | 12.13 Ib |

| System 15 250mm Section | 17.64 in | 17.64 Ib |

| System 15 500mm Section | 26.46 in | 26.46 Ib |

| System 15 1000mm Section | 46.29 in | 46.29 Ib |

| System 15 2000mm Section | 83.78 in | 83.78 Ib |

SYSTEM 15 ACCESSORIES

| DESCRIPTION |

|---|

| 1. System 30 Jack |

| 2. Raking Bracket |

| 3. End Plate |

| 4. End Connector |

| 5. Needle Beam Fixing Clamp |

| 6. Truss Fixing Bracket |

SYSTEM 15 SCREW JACK SPECIFICATIONS

| DESCRIPTION | WEIGHT | ADJUSTMENT | BASE |

|---|---|---|---|

| SCREW JACK | 16kg 35.27 Ib |

400 ~ 610mm 15.75~24.02in |

190 × 140mm 7.45 × 5.51in |

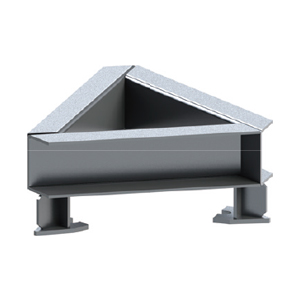

TRISHORES

A proven propping system

Trishore Props are a heavy load support system with capacity up to 178Kn. The Trishore Props are best utilized when support is

required at extended heights.

Trishore Advantages

- Able to support heavy at considerable height

- Fine adjustment by screw jacks

- Trishores braced in groups can support exceptionally heavy loads

- Lightweight sections for easy handling

Trishore Props are a heavy load support system with capacity up to 178Kn. The Trishore Props are best utilized when support is

required at extended heights.

Trishore Advantages

- Able to support heavy at considerable height

- Fine adjustment by screw jacks

- Trishores braced in groups can support exceptionally heavy loads

- Lightweight sections for easy handling

Features

- Intermediate sections available in three different lengths

- Domed bearing plate to ensure concentric loading

- Quick action connector

- Intermediate sections available in three different lengths

- Domed bearing plate to ensure concentric loading

- Quick action connector

TRISHORE SECTION / COMPONENT SPECIFICATIONS

- mm/kg

- in/lb

| DESCRIPTION | LENGTH | WEIGHT |

|---|---|---|

| Intermediate Section | 1250mm | 28kg |

| Intermediate Section | 1500mm | 33kg |

| Intermediate Section | 2000mm | 41kg |

| Flat Head Piece | 170mm | 14kg |

| Base Jack | From 365~640mm | 34kg |

| Head Jack | From 380~670mm | 32kg |

| DESCRIPTION | LENGTH | WEIGHT |

|---|---|---|

| Intermediate Section | 49.21 in | 81.73 Ib |

| Intermediate Section | 59.06 in | 72.75 Ib |

| Intermediate Section | 78.74 in | 90.39 Ib |

| Flat Head Piece | 6.69 in | 30.86 Ib |

| Base Jack | From 14.37~25.19 in | 74.95 Ib |

| Head Jack | From 14.96~26.38 in | 70.55 Ib |

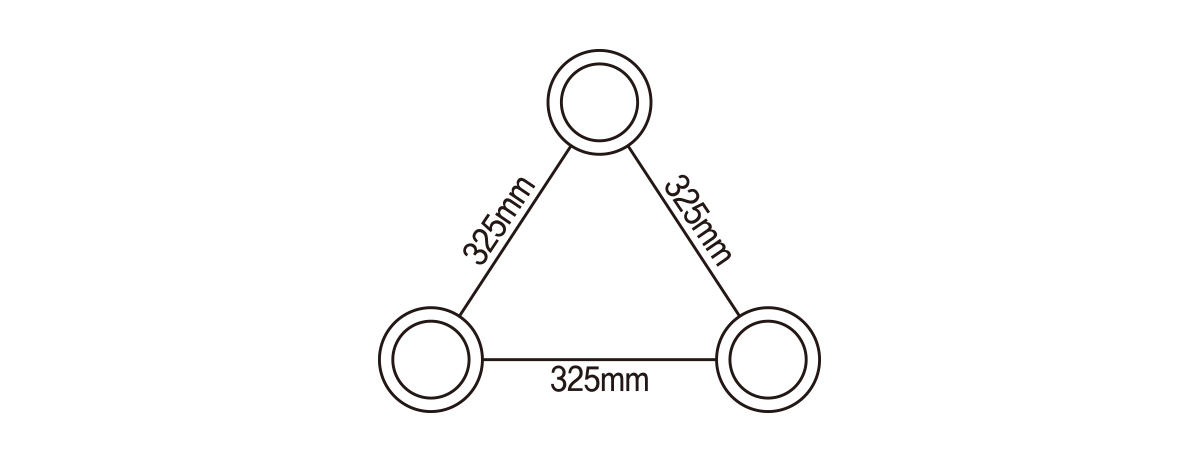

Trishore Qutside Dimensions

Trishore Components

-

Base Jack

-

-

Head Jack

-

-

Flat Head Piece

-

Dimensions

The working load limi given is for a free standing prop without intermediate bracing. Prop load rating can be increased by providing

a dequate bracing at intermediate points (to be calculated by a qualified engineer).

To be effective, the bracing must be in two directions, preferably at right angles. In every case, some cross bracing is essential for

erection and stabilising against any lateral force. Bracing is to be correctly fitted to Australian Standards requirements.

a dequate bracing at intermediate points (to be calculated by a qualified engineer).

To be effective, the bracing must be in two directions, preferably at right angles. In every case, some cross bracing is essential for

erection and stabilising against any lateral force. Bracing is to be correctly fitted to Australian Standards requirements.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)