Product

Human Respect Development Center, DKS HRDC

Mega Beam 1000

DKS Heavy Duty Shoring System

Structural shoring- light, medium and

heavy duty systems for structural support

- Maintenance for Bridge construction

- Support for Stadium steel frame

- Support for Airport steel frame

- Historical building facade retention

- Building remodeling and gantry setup

- Temporary support for City rail road

- Tunnel construction

- Support for Stadium steel frame

- Support for Airport steel frame

- Historical building facade retention

- Building remodeling and gantry setup

- Temporary support for City rail road

- Tunnel construction

Overview

Mega Beam is a versatile temporary modular heavy-duty propping system that can be adapted to the most demanding projects on construction sites. Its most frequent uses are the support of bridges, superstructures and ground shoring applications.

-

FASTER

It is one of the f astest, most efficient and v ersatile ways to provide quick support and access solutions in a wide v ariety of situations, using only two main components, the base jack and heavy-duty mega beam. -

SAFER

Mega beam system allows our customers to safely, reliably and efficiently develop and complete infrastructure projects.

This system is guaranteed to make your project safer and more productive

Australia, Sydney construction site of Brand Corp., using Mega beam. Manufacturer: DKS Global.

-

-

-

INCYE construction site. New access to Cordoba Airport

-

In Detail

Gwangandaegyo Bridge, DL Cosn., Posco & Lotte construction site, Engineered by RMD Korea, Manufacture and Supervised: DKS Global

-

Multiple Size

Mega beam is manufactured in eight lengths, 5400, 2700, 1800, 900, 450, 270, 90 and 15mm so a prop of any length can be created.Quality

Using accurate welding jigs, manufactured from high yield steel, combining maximum durability and load capacity with reduced unit weight, complete by hot dip galvanizing, eliminates corrosion and minimizes maintenance.Compatibility

1000kN massive axial load capacity and high axial stiffness. Mega Beam can be adapted to the demands of heavy formwork, cofferdams, bridge decks and more.

Mega Beam 1000 can be used as the backbone of the bridge with minimal traffic flow disruption. -

-

Gyeongbuk High-Speed Rail Construction site, RMD Korea, Manufacturer: DKS Global.

The Mega Beam system is engineered to minimize labor costs, increase site productivity, improve work site safety and meet the requirements of current construction and civil engineering techniques.

Mega Beam must always be used by experienced personnel and have multi-directional support.

Mega Beam must always be used by experienced personnel and have multi-directional support.

3D model of diverse use of Mega Beams

Mega / Waler Beram Site

Ambassador Hotels Remodeling Construction site.

Mega and Waler beam has used to built pedestrian sidewalk during remodeling work.

Address: 78, Namdaemun-ro, Jung-gu, Seoul, Korea

Total Length: 60m

Duration: August ~ September, 2020

Mega and Waler beam has used to built pedestrian sidewalk during remodeling work.

Address: 78, Namdaemun-ro, Jung-gu, Seoul, Korea

Total Length: 60m

Duration: August ~ September, 2020

Application

DKS will not stuck in the pr esent satisfaction,

but take up the challenges f or creativity’s sake.

but take up the challenges f or creativity’s sake.

INCYE construction site. Aqua Hotel, Barcelona

Mega Beam temporary sections, which are robust and easy to assemble, can be used in many temporary work applications such as :

- Cofferdams

- Bridge propping and hydraulic jacking

- Facade retention

- Ground shoring and excavation support

- Construction of lifting rigs

- When used in ㅅand tunnel formwork

- Heavy duty falsework

Mega Beam Shoring-Equipment engineered to prevent excavation collapses by actively retaining soil, preventing earth movement

and protecting adjacent structures.

- Cofferdams

- Bridge propping and hydraulic jacking

- Facade retention

- Ground shoring and excavation support

- Construction of lifting rigs

- When used in ㅅand tunnel formwork

- Heavy duty falsework

Mega Beam Shoring-Equipment engineered to prevent excavation collapses by actively retaining soil, preventing earth movement

and protecting adjacent structures.

3D model of diverse use of Mega Beams

Can be assembled as tower as well as Pillar

Mega Beam is one of the most versatile modular shoring and propping systems with holes in both the flanges and the webs, alwa ys the systems to be built up into a number of different configurations from shoring stiff, towers. This system can be quickly and easily built of various configurations including propping and modular brace tower which is efficient for large construction like stadium, airports and others.

-

-

-

-

-

Ideal as primary beams

Mega / Walerbeam are ideal as primary beams on shoring or scaffolding to supp ortreinforced concrete slab construction.

Mega Beam Punchings

Dimensions

- mm/kg

- in/lb

| CODE | PRODUCT | DESCRIPTION | WEIGHT |

|---|---|---|---|

| DMB5400 | MB Leg 5400mm | 5400mm | 316.0 kg |

| DMB4500 | MB Leg 4500mm | 4500mm | 266.0 kg |

| DMB2700 | MB Leg 2700mm | 2700mm | 160.0 kg |

| DMB1800 | MB Leg 1800mm | 1800mm | 112.0 kg |

| DMB0900 | MB Leg 900mm | 900mm | 65.0 kg |

| DMB0450 | MB Leg 450mm | 450mm | 45.0 kg |

| DMB0270 | MB Leg 270mm | 270mm | 35.0 kg |

| DMB0090 | MB Leg 90mm | 90mm | 25.0 kg |

| DMB0015 | MB Leg 15mm E/P | 15mm | 10.0 kg |

| CODE | PRODUCT | DESCRIPTION | WEIGHT |

|---|---|---|---|

| DMB5400 | MB Leg 5400mm | 212.6 in | 696.7 lb |

| DMB4500 | MB Leg 4500mm | 177.2 in | 586.4 lb |

| DMB2700 | MB Leg 2700mm | 106.3 in | 352.7 lb |

| DMB1800 | MB Leg 1800mm | 70.9 in | 246.9 lb |

| DMB0900 | MB Leg 900mm | 35.4 in | 143.3 lb |

| DMB0450 | MB Leg 450mm | 17.7 in | 99.2 lb |

| DMB0270 | MB Leg 270mm | 10.6 in | 77.2 lb |

| DMB0090 | MB Leg 90mm | 3.5 in | 55.1 lb |

| DMB0015 | MB Leg 15mm E/P | 0.6 in | 22.0 lb |

Components

-

Screw Jack 100Ton Code DSJ 100TON Product Screw Jack 100Ton Description 400×660mm Weight 66kg -

-

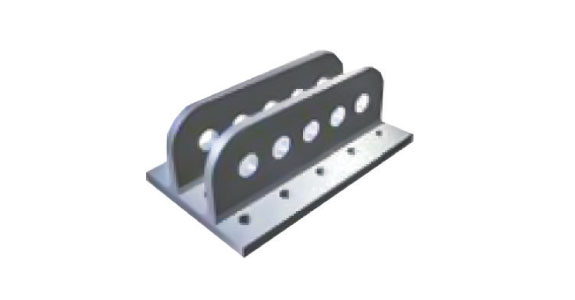

Brace Plate Code DMB 02 Product Brace Plate Description 500×500mm Weight 60kg -

-

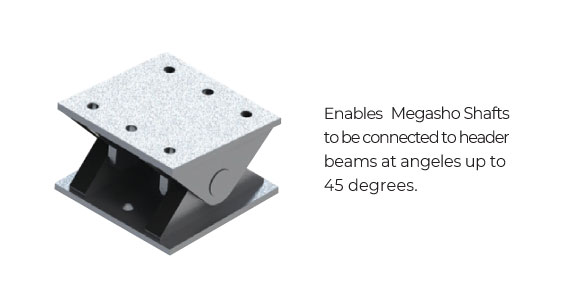

Rocking Head Code DMB 03 Product Rocking Head Description 300×248mm Weight 47kg -

-

Push Pull Tilt Plate Code DMB 04 Product Push Pull Tilt Plate Description - Weight 49kg -

-

Jack Plate Code DMB 05 Product Jack Plate Description 290×290×40mm Weight 26kg -

-

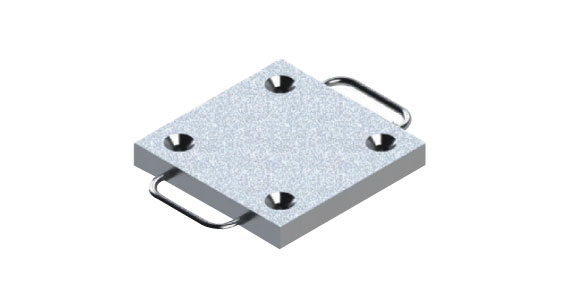

End Plate Code DMB 06 Product End Plate Description 290×290mm Weight 9.5kg -

-

Hydraulic Unit Code DMB 07 Product Hydraulic Unit Description 400×610mm Weight 137kg -

-

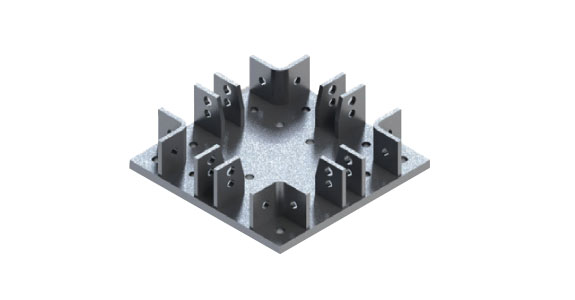

Mega Truss Node Code DMB 08 Product Mega Truss Node Description - Weight 49kg -

Test Report

| NO | Max load(kN) | Result | Remark |

|---|---|---|---|

| Test 1 | 1894(190t) | No changes in sample |

- |

| Test 2 | 1894(190t) | No changes in sample |

- |

| Test 3 | 1898(190t) | No changes in sample |

- |

* The maximum load capacity of the machine was 2000kN, But the load machine automatically stopped on the above load for safery.

Mega Beam1000

-

-

-

Mega Beam Technical Data

Mega Beam is ideal for the Building and refurbishment market, this is one of the most v ersatile mo dular shoring and propping systems available in the world.

Using a lar ge range of of f-the-shelf components with holes in b oth the flanges and the webs, allows the systems to be built up into a numb er of different configurations.

.jpg)

.jpg)

_v2.jpg)

.jpg)

_v3.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

_v2.jpg)

.jpg)

.jpg)